Products

Our Seals

Benefits of our seals

Avoid tampering

guarantee the authenticity of the product

avoid spills/loss

Protect the environment

guarantee the freshness of the product

extend product life

avoid product contamination

achieve a hermetic closure of the container

boost sales

cost savings

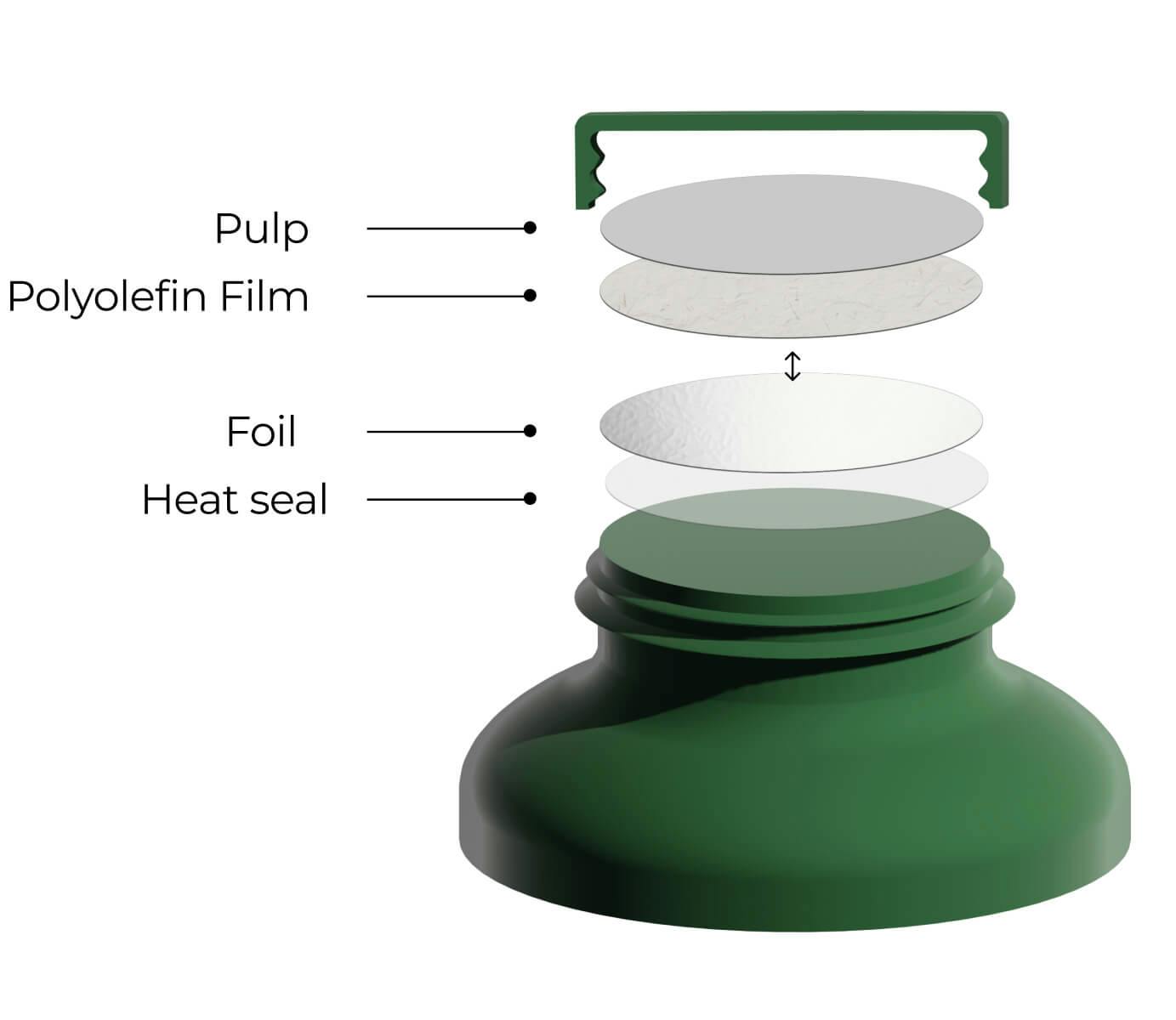

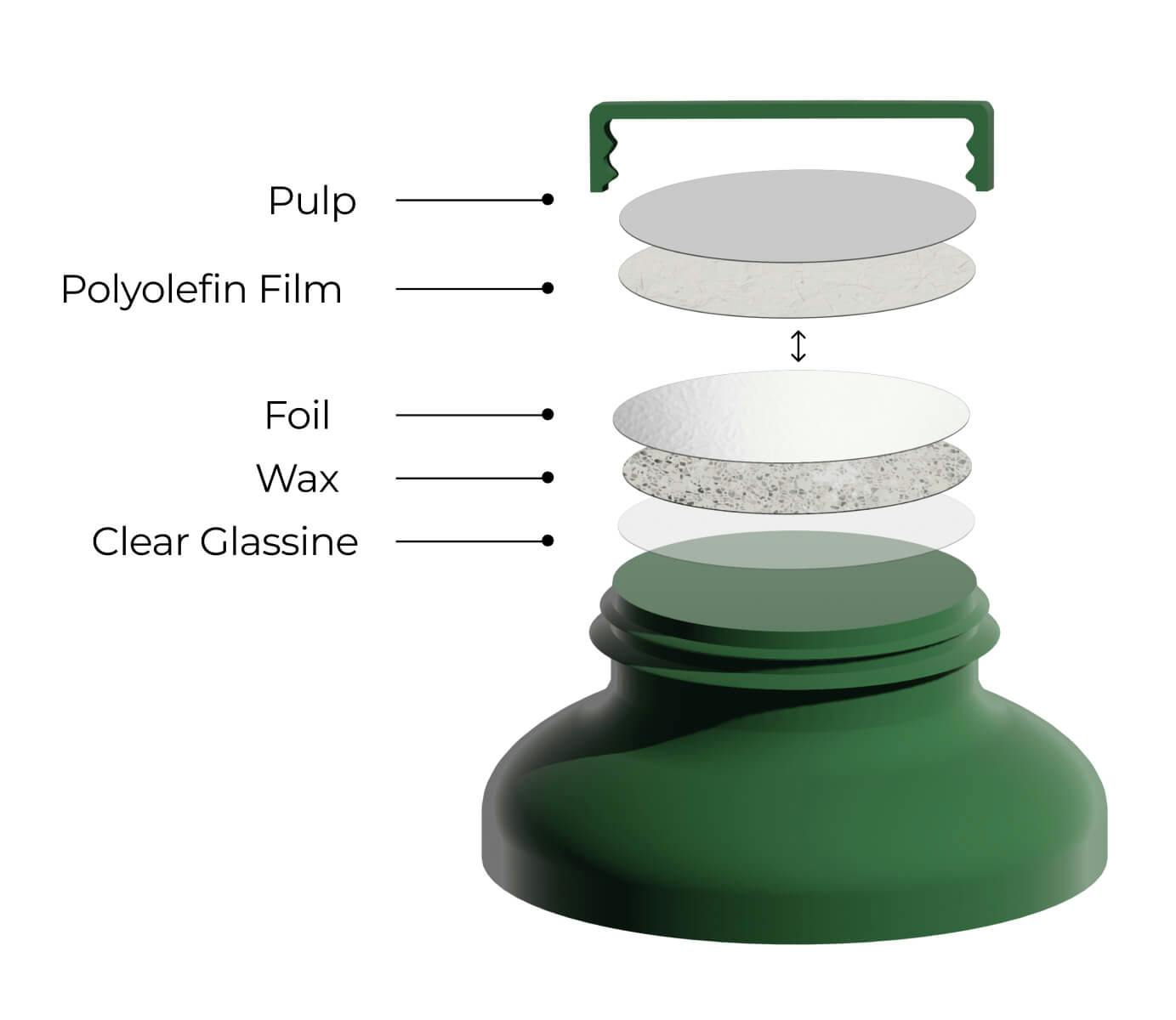

Induction Liners

Induction sealing is a unique non-contact heating process that hermetically seals a container. Induction heat is one of the most effective sealing methods for almost all types of containers (Plastic, glass, etc).

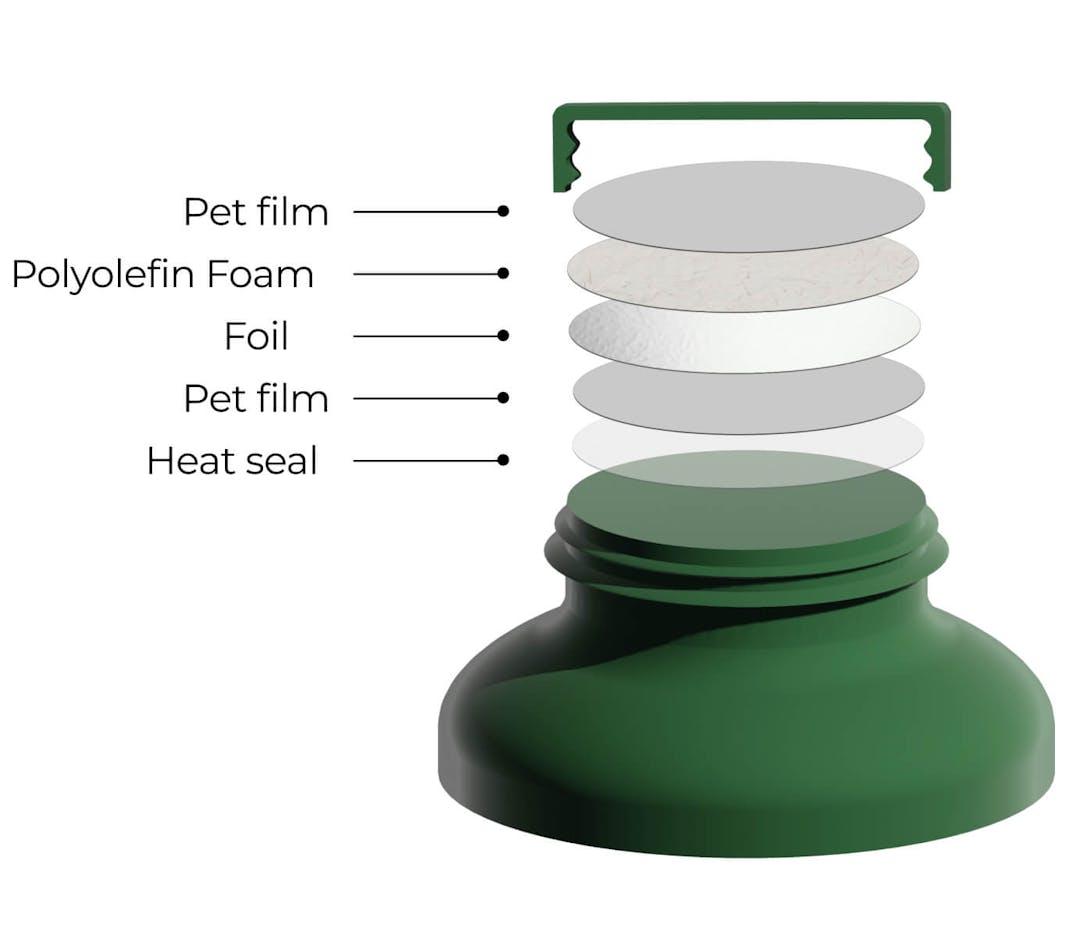

Uni-Gard

Uni-Gard™ is a range of one piece induction seals that provide positive production benefits such as higher operating speeds, and provides greater packaging confidence as well. Both peelable and welded products are available with custom prints for product differentiation and to add value to your packaging.

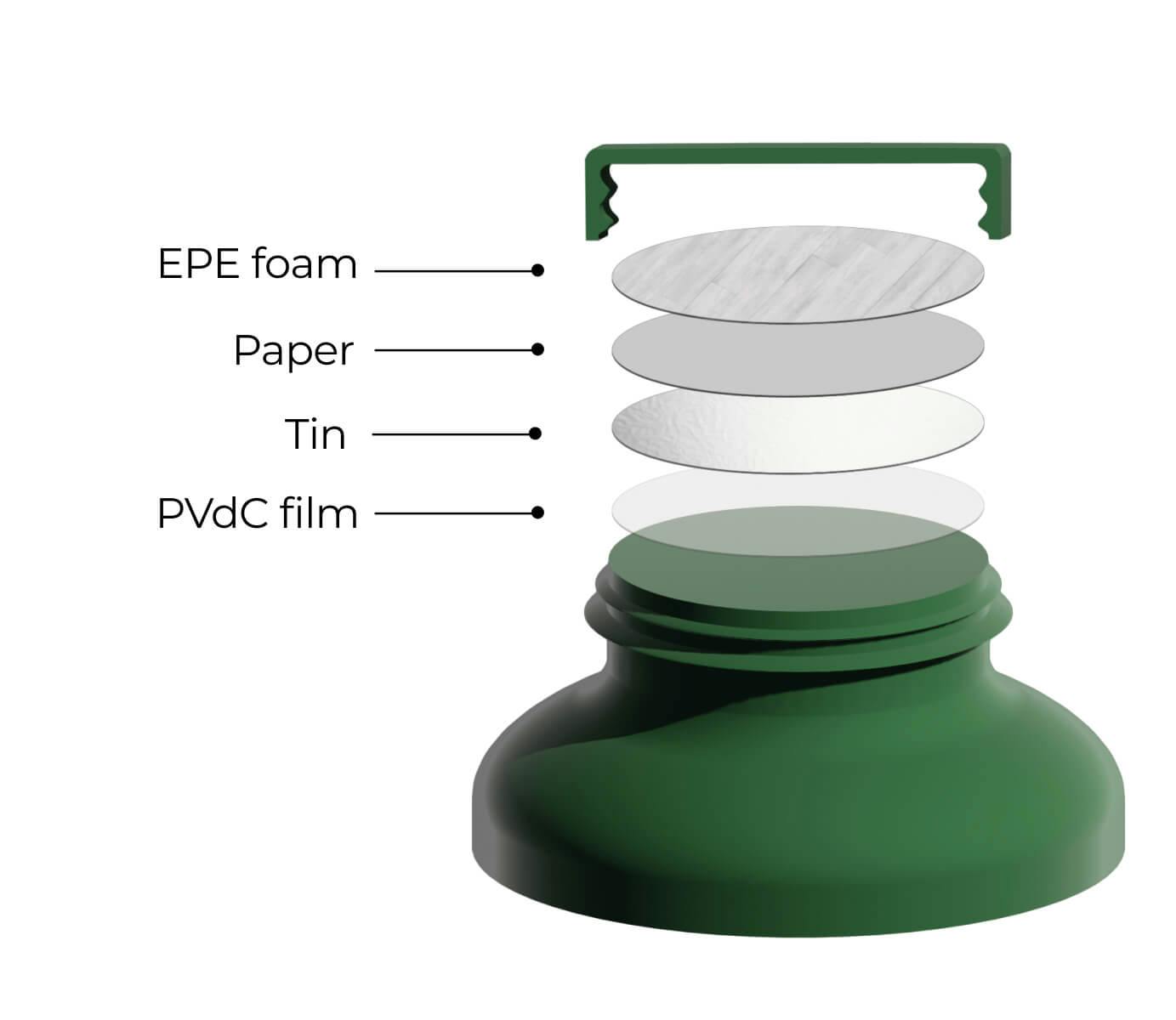

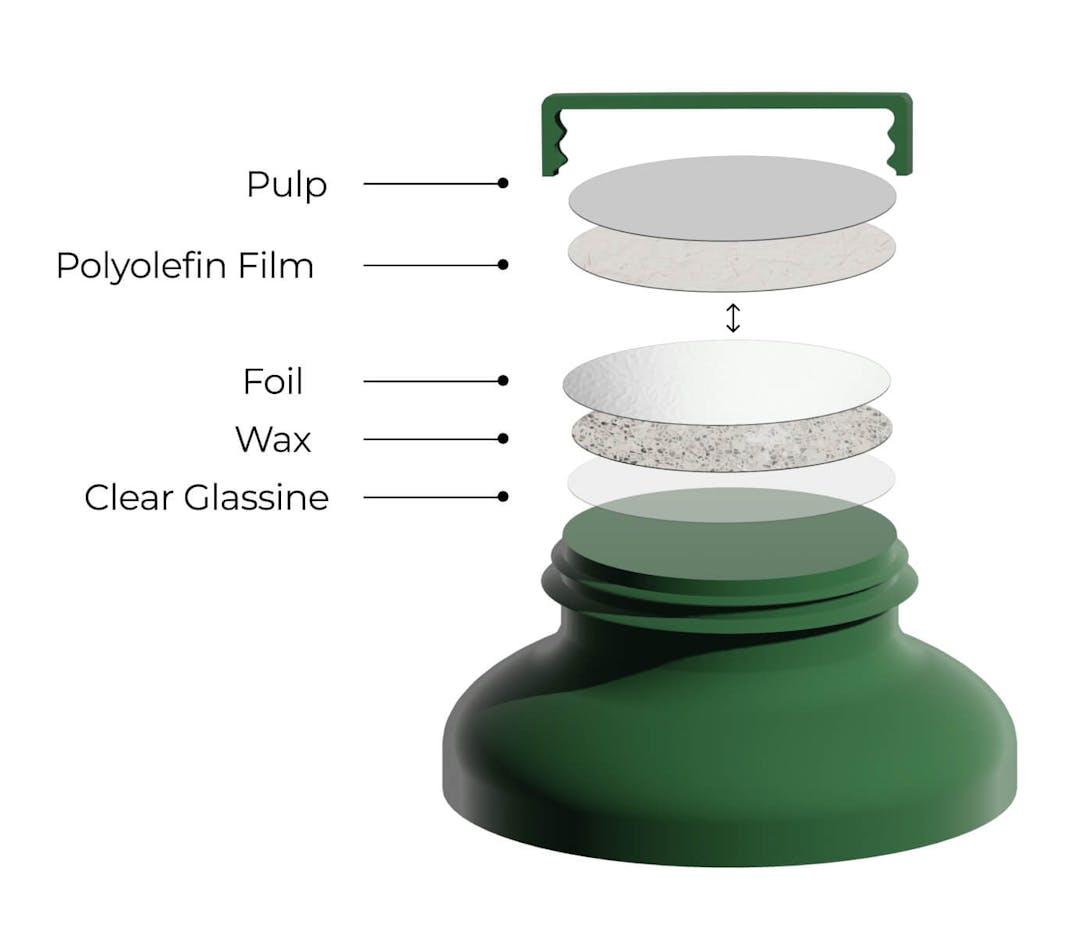

Glue Liners

Immediately after the containers are filled, glue is applied to the bottle neck’s surface and then the caps (already equipped with the glue liner) are screwed on. Glue liners display excellent tamper evidence and are often used for dry/powdered beverages such as coffee and chocolate drinks, as well as spices and seasonings on glass packages.

QUADRASEAL™

Upon removal of the closure the QUADRASEAL™ liner gives an audible ‘crack’ during separation. The materials separate to leave a clean foil on the container and a polymer-faced reseal liner in the cap.

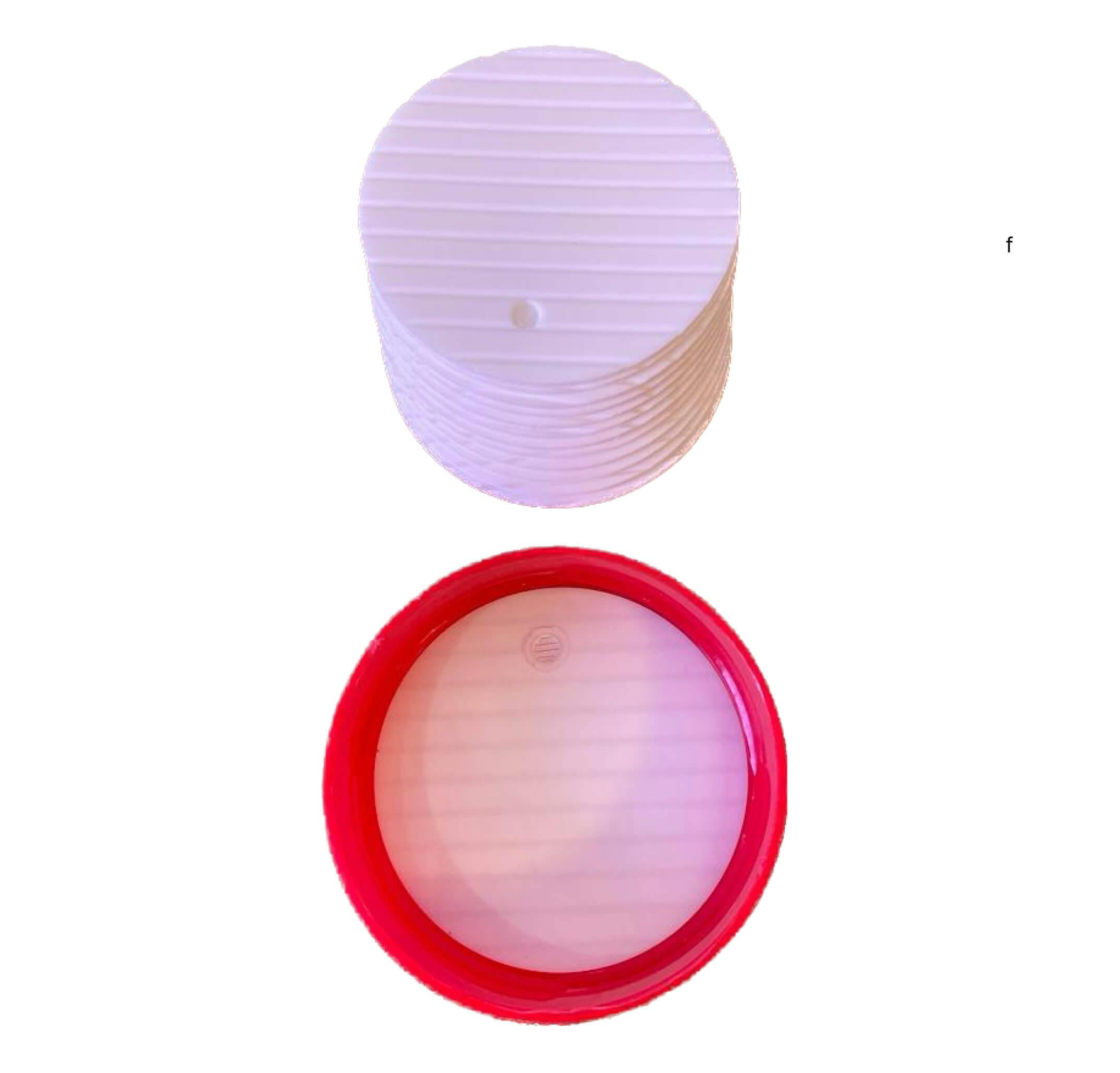

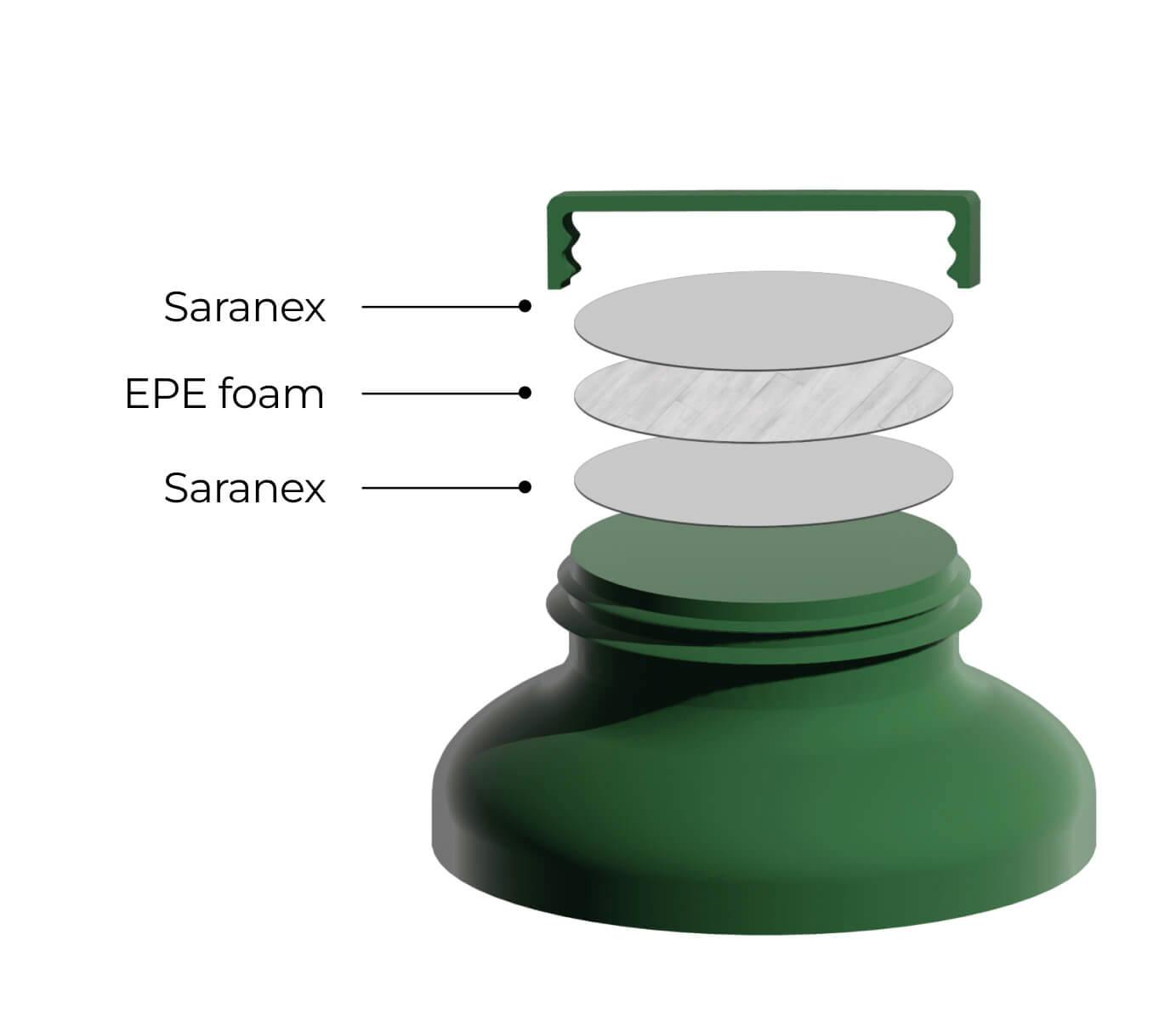

PS Liners

A pressure sensitive liner is a polystyrene foam coated with adhesive on one side. The adhesive is later torque-activated when the lid is screwed onto the container. As a result, these liners achieve very good adhesion to glass and plastic containers without using a sealing machine.

PS-113

The PS-113 liner is inserted into the screw cap and then sealed by pressure. This liner will successfully remain on the container after the removal of the closure.

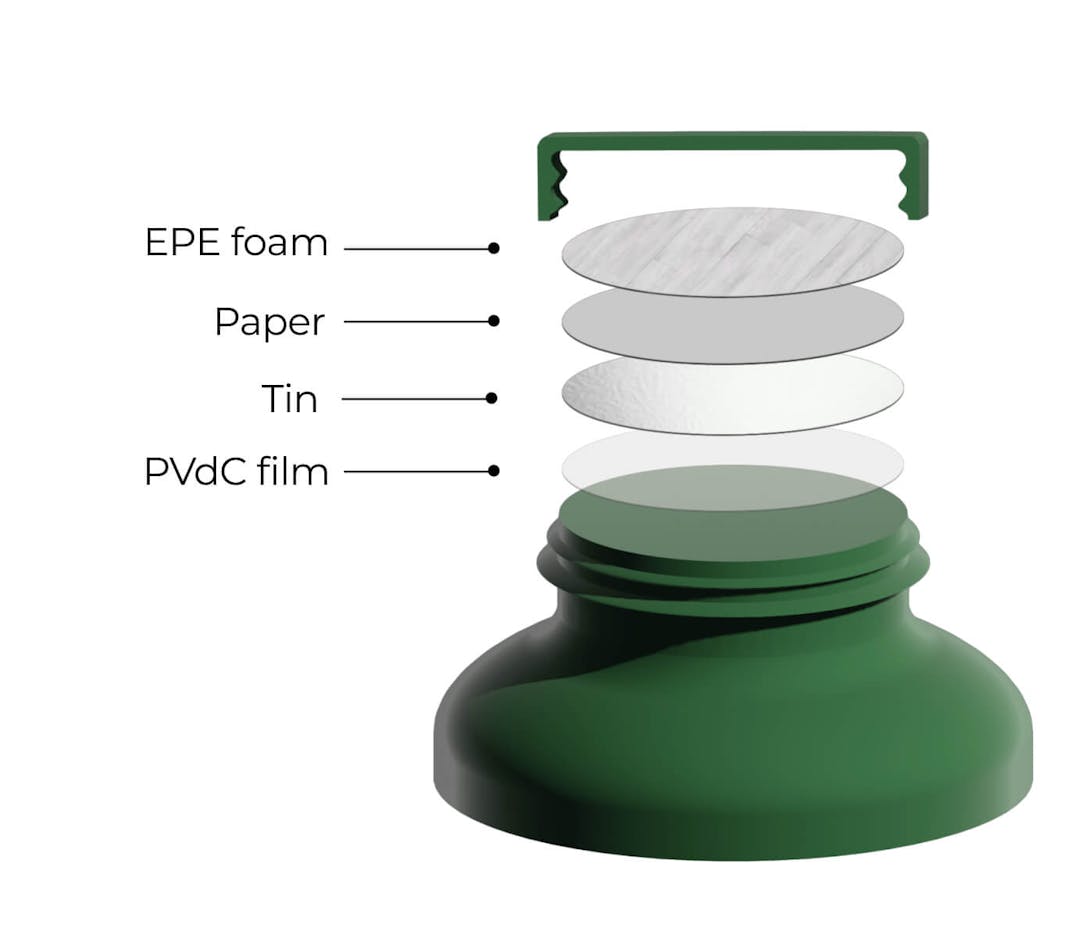

Foam-Based and Traditional Liners

These primary base liners represent the most basic approach to protect a product without tamper evidence. They help prevent leaks, avoid contact with moisture, oxygen ingress, loss of aromas and maintain the shelf life of the active ingredients.

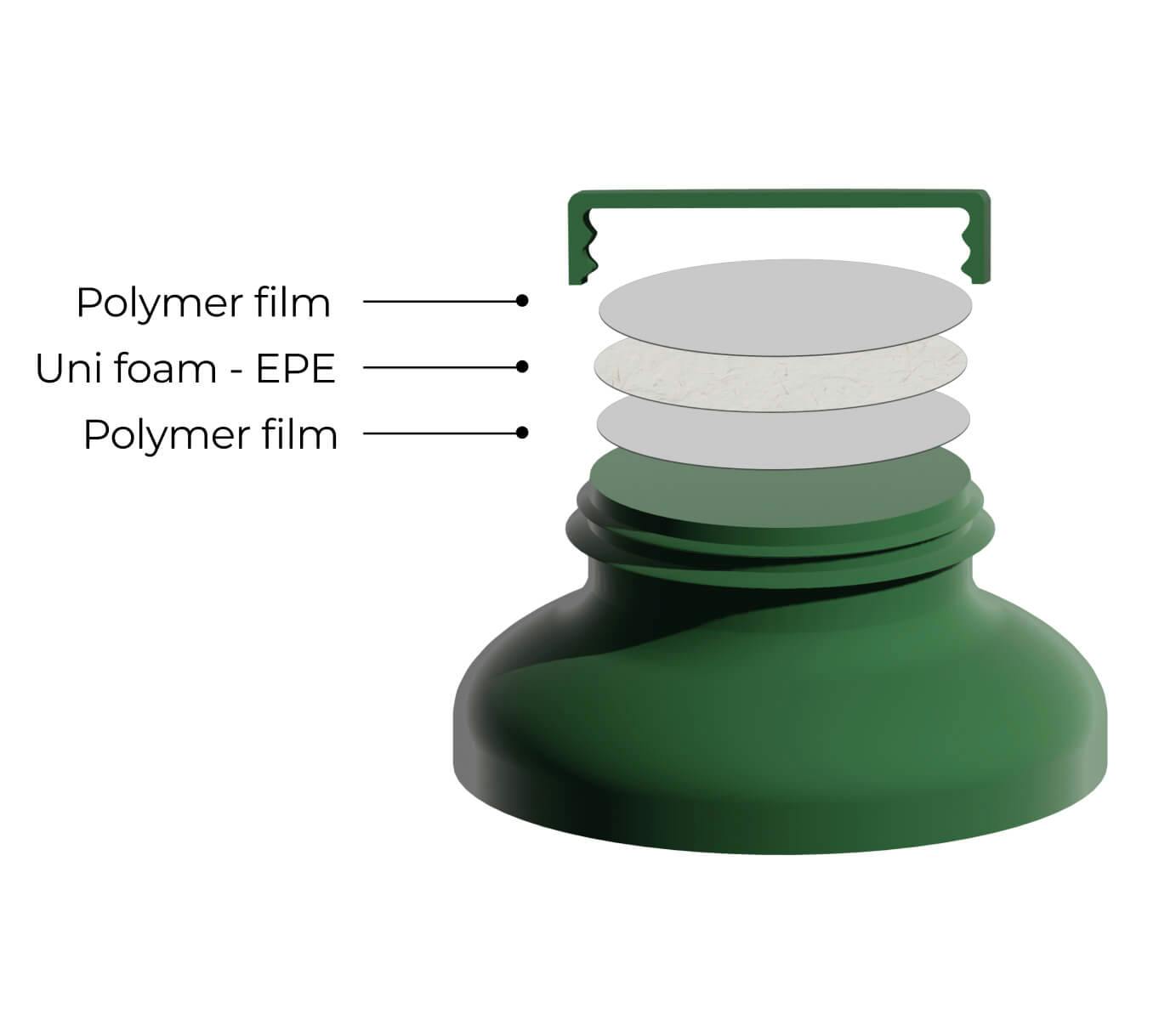

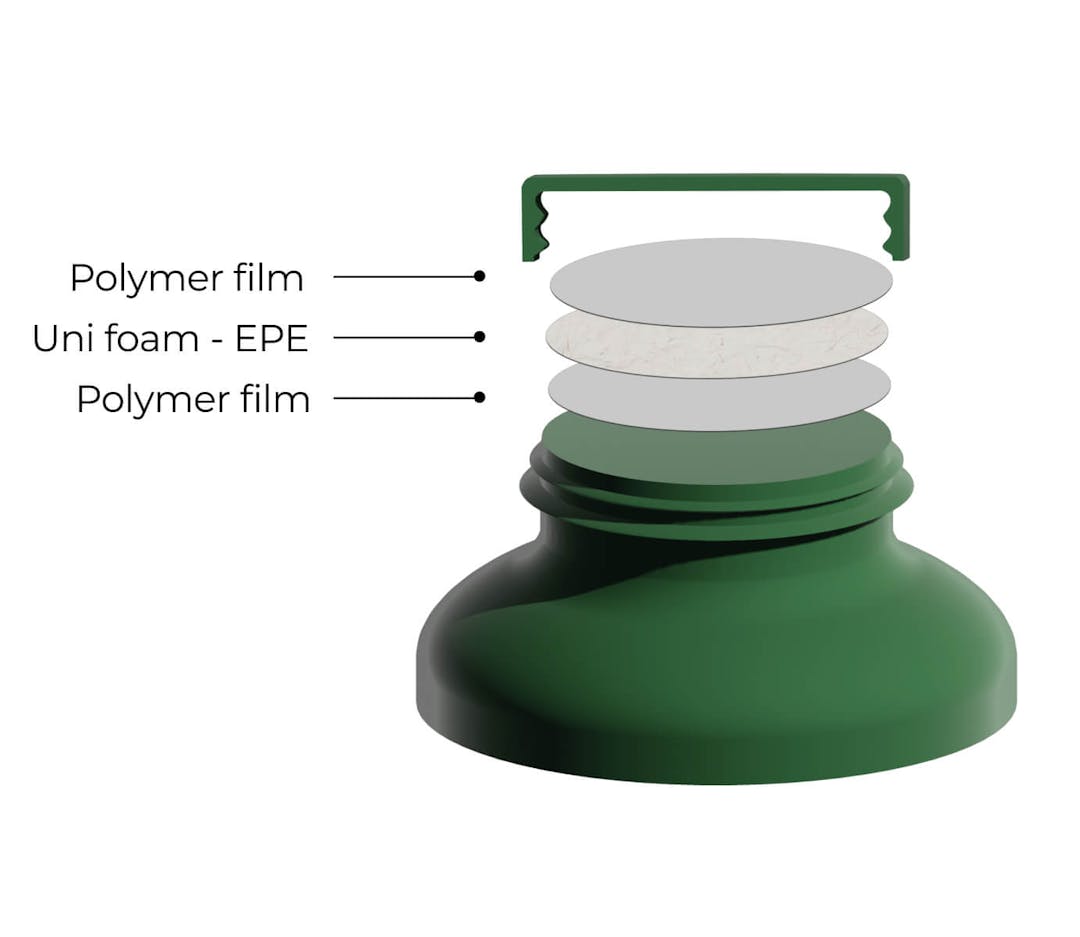

UNI-FOAM ™

Uni-Foam™ is a range of EPE (or EPP) foam based lining materials which provide a dust free, non-absorbent sealing solution. Our material remains unaffected by ambient temperatures and the opaque white foam create a high quality visual aesthetic.

Venting Solutions

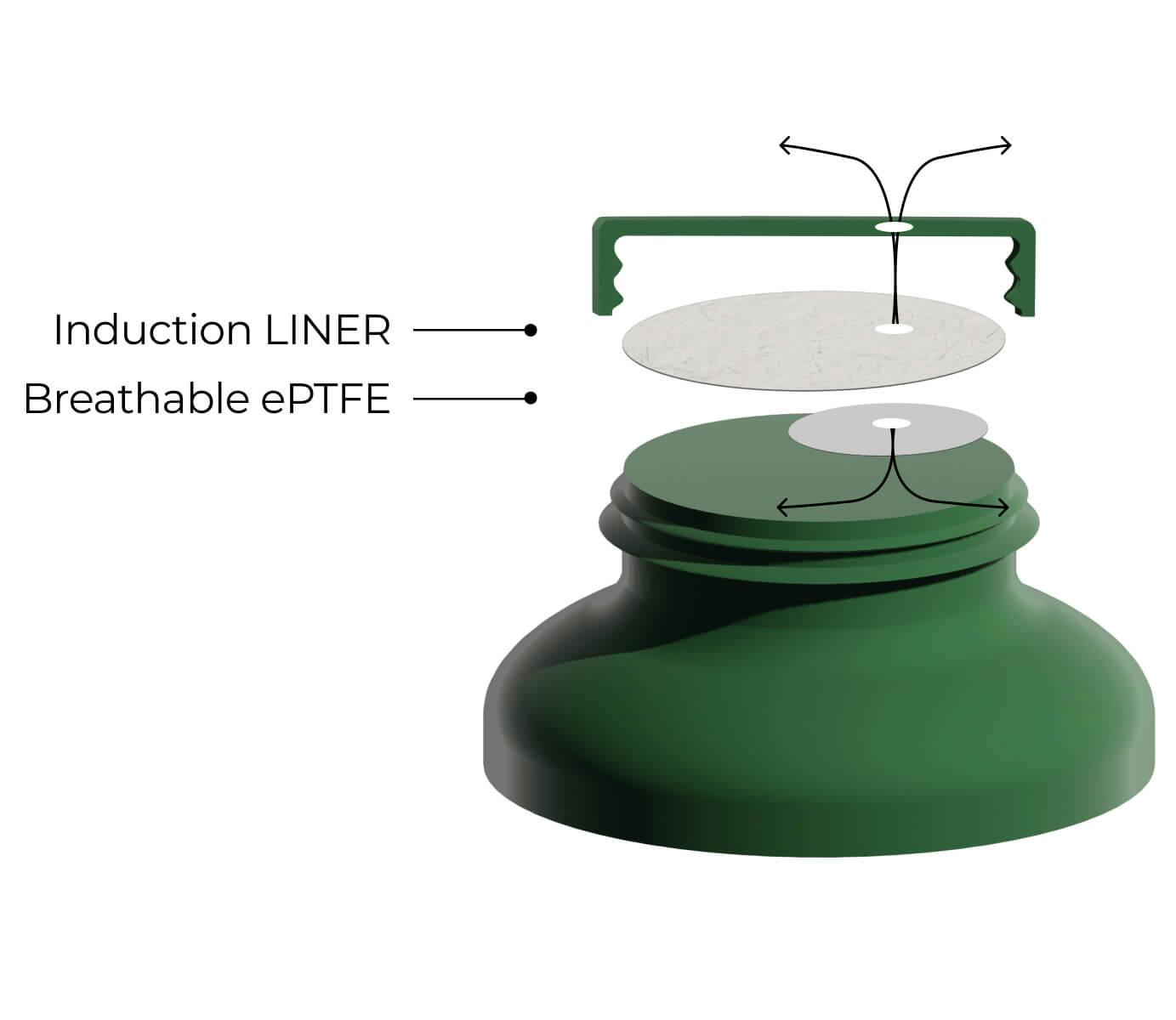

Packaging is more complex than ever, and so are the challenges of vented sealing. Our venting solutions let products breathe and allow gas exchange in both directions. As a result, our vented seals prevent any distortion and rupture of a container.

Our vented seals consist of our proprietary breathable ePTFE, along with a range of other materials. The seals are ideal for agrochemicals and household cleaners.

CIRCUMVENT

his patented material lets air flow in both directions to prevent package swelling and collapse. Circumvent® repels water and ensures there's no spillage or loss. In addition, Circumvent® seals have broad chemical compatibility and it is used as a grooved material.

Wine Solutions

Change is on the horizon for wine packaging. For many years the glass bottle and cork have seemed like a match made in heaven. However, over recent years, issues with cork taint have led to wine providers exploring other options.

Today, hundreds of millions of caps are wadded with œnoseal® liners worldwide. The liner is a multi-layer product located at the bottom of the cap, each layer providing a different barrier level.

œnoseal® liner is an essential alternative to traditional corks, not only because they do not develop TCA (the molecule responsible for contaminating wine and giving 'tainted' wine) but also because, with equal ageing and preservation performances, the lined cap is cheaper than a cork.

Oenoseal® S

Oenoseal® is the world's N1 liner for wine! The liner guarantees leading edge technical solutions regardless of the type of closure used and irrespective of the qualities of your wine.

Colectora Oeste Ramal Pilar,

Km 43,2 (1669), Del Viso, Pilar.

Provincia de Buenos Aires

Copyright © 2022 Oscilon All rights reserved